A workshop is more than just a space; it’s where ideas come to life, projects take shape, and productivity thrives. Whether you’re a woodworker, mechanic, artist, or DIY enthusiast, having a well-designed, custom-built shop can make all the difference in efficiency, comfort, and results.

However, many people struggle with their workspace. Some try to make do with cluttered garages, while others attempt to work in poorly lit, cramped, or disorganized spaces that hinder creativity and productivity.

If you’ve ever found yourself frustrated by your workshop’s limitations, you’re not alone. The good news? A custom-built shop tailored to your specific needs can solve all these problems while increasing the value of your property.

Additionally, with the rise of same-day delivery service for local shops, it’s now easier than ever to get tools, materials, and supplies delivered right when you need them—keeping your projects on track and minimizing downtime.

In this guide, we’ll explore everything you need to know about designing the perfect workshop, from choosing the right size and layout to lighting, storage, flooring, and power needs.

Why a Custom Workshop is Better than a Generic Space

Many people start with whatever space is available—a garage, shed, basement, or even an unused bedroom. But these spaces often come with limitations:

- Lack of space: Standard garages and sheds are often too small for tools, workbenches, and storage.

- Poor lighting and ventilation: A single overhead bulb isn’t enough, and lack of airflow can make work environments unsafe.

- Clutter and disorganization: Without custom storage solutions, tools and materials pile up, creating inefficiencies.

- Noise issues: Many workshops are noisy, disturbing family members or neighbors.

Instead of working within these limitations, a custom workshop allows you to design a space that perfectly matches your workflow, tools, and long-term goals.

Planning Your Custom Workshop: A Step-by-Step Approach

Before breaking ground on your dream workshop, careful planning is essential. Here’s how to get started:

1. Determining the Right Size and Layout

One of the biggest advantages of a custom shop is having control over its size and design. When determining the best layout, ask yourself:

- How much space do you need? Consider both current and future equipment.

- What’s your workflow? Arrange workstations logically to minimize unnecessary movement.

- Will your shop serve multiple purposes? Some people combine their shop with office space, storage, or even a showroom.

Optimizing Workshop Layout for Efficiency

Your layout should be designed for maximum efficiency. A well-planned workshop follows these key principles:

- Clear pathways: Ensure enough space to move freely between workstations.

- Dedicated work zones: Separate areas for cutting, assembling, finishing, and storage.

- Logical tool placement: Keep frequently used tools easily accessible.

🔹 Example Layouts:

- Small Shops (200-400 sq ft): Ideal for hobbyists, focusing on compact storage and multi-functional workbenches.

- Medium Shops (500-800 sq ft): Suitable for serious DIYers or small business owners, allowing for dedicated zones.

- Large Shops (1000+ sq ft): Best for commercial use, accommodating industrial tools, vehicles, and additional storage.

2. Prioritizing Lighting and Ventilation

A well-lit and ventilated shop is essential for both safety and comfort.

Choosing the Right Lighting

Poor lighting can lead to eye strain, inaccurate measurements, and even safety hazards. Consider the following lighting options:

- Natural light: Large windows and skylights can reduce energy costs while improving visibility.

- Overhead LED lighting: LED lights provide bright, energy-efficient illumination.

- Task lighting: Adjustable lamps help in detailed work like carving, wiring, or painting.

🔹 Pro Tip: Install color-balanced LED lights (5000K-6000K) for true-to-life colors in painting and woodworking.

Ensuring Proper Ventilation

Proper ventilation is critical—especially for woodworking, welding, or painting. Without it, dust, fumes, and heat can quickly make a space uncomfortable and unsafe.

- Exhaust fans: Remove dust and fumes from enclosed spaces.

- Cross-ventilation: Place windows on opposite walls for natural airflow.

- Dust collection systems: Essential for woodworking shops to prevent fine dust from accumulating.

3. Optimizing Storage and Organization

A cluttered workshop can slow down productivity and even lead to accidents. Smart storage solutions help keep tools organized and within easy reach.

Storage Ideas for Every Workshop

- Wall-mounted racks and pegboards: Perfect for storing frequently used tools.

- Overhead storage: Utilize ceiling space for seasonal or infrequently used items.

- Mobile storage carts: Allow flexibility and keep essential tools close to your work area.

- Custom-built cabinets: Offer concealed storage for materials and supplies.

🔹 Pro Tip: Organize tools by function (cutting, assembly, measuring, etc.) for quick access.

4. Choosing the Right Flooring and Insulation

Your workshop floor needs to be durable, safe, and easy to maintain.

Best Flooring Options for Workshops

- Concrete flooring: Strong, durable, and easy to clean.

- Rubber mats: Provide comfort for standing long hours and reduce tool damage if dropped.

- Epoxy coatings: Add durability and chemical resistance.

Insulation for Year-Round Comfort

- Spray foam insulation: Ideal for sealing gaps and preventing heat loss.

- Rigid foam boards: Effective for walls and ceilings.

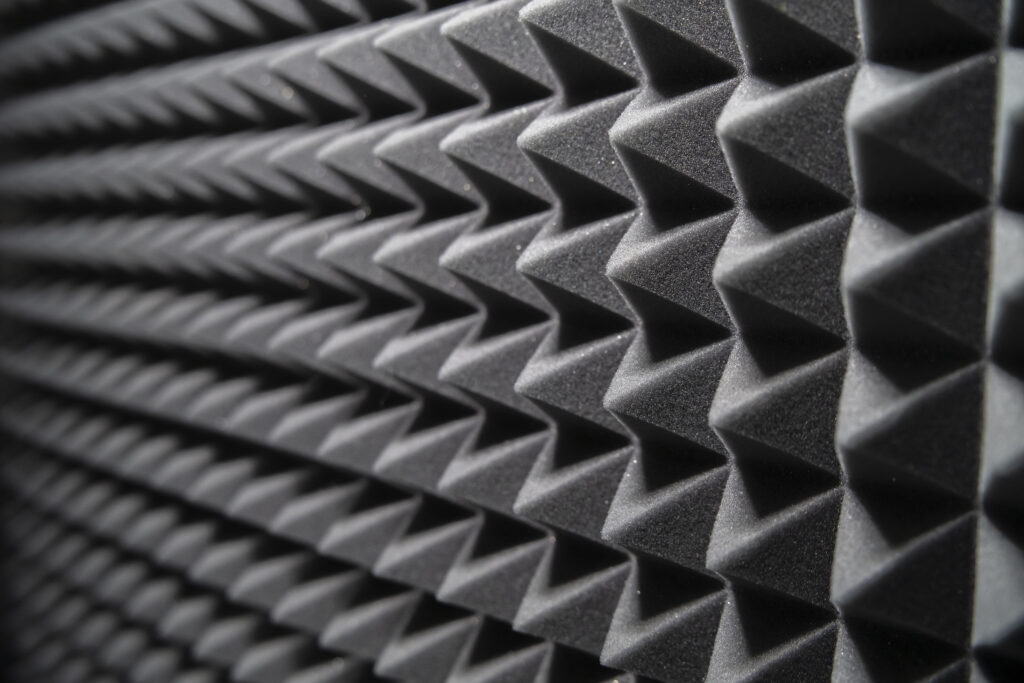

- Soundproofing panels: Useful for reducing noise, especially in residential areas.

5. Meeting Technology and Power Needs

Modern workshops aren’t just about tools—they require smart technology and power solutions to function efficiently.

Electrical and Power Planning

- Multiple power outlets: Prevent overloading circuits by spacing outlets every 4-6 feet.

- Dedicated circuits: Heavy-duty tools like table saws and welders need dedicated 220V circuits.

- Surge protectors: Protect valuable equipment from power fluctuations.

Smart Workshop Features

- Wi-Fi integration: Use smart devices to control lighting, security, and ventilation.

- Automated dust collection: Connect systems to turn on when tools are in use.

- Climate control: Smart thermostats maintain a comfortable working temperature.

Additional Considerations for a Long-Lasting Workshop

Safety First

A well-designed workshop should prioritize safety. Key safety features include:

- Fire extinguishers and smoke detectors.

- Non-slip flooring to prevent accidents.

- First-aid kits for minor injuries.

Enhancing Aesthetics and Comfort

While functionality is key, aesthetics matter too! A well-designed shop can be motivating and inspiring.

- Paint walls in light colors to improve brightness.

- Add seating areas for brainstorming and relaxation.

- Personalize with posters, artwork, or motivational quotes.

Final Thoughts: Build a Workshop That Works for You

Your workshop should be a space that inspires productivity, efficiency, and creativity. By designing a custom shop tailored to your specific needs, you can create a workspace that not only meets your current requirements but also grows with you over time. Plus, with the convenience of same-day delivery service for local shops, getting the tools and materials you need has never been easier or faster—helping you stay focused and efficient.

Ready to build the workshop of your dreams? No7 Development specializes in designing and constructing custom shops that perfectly match your needs. Contact us today and take the first step toward a more productive and enjoyable workspace!